Scaling Up Artisanal Recipes for Professional Kitchens Without Losing Authenticity

This article explores best practices and techniques to scale artisanal recipes while retaining the soul of the craft, ensuring that each bite still tells the same story of quality and care — no matter where it’s produced.

Why Scaling Artisan Baking Is a Strategic Advantage

In today's competitive foodservice landscape, the ability to reproduce high-quality, artisan-style baked goods in volume has become a critical differentiator. With the growing popularity of sourdough breads, rustic loaves, and naturally fermented products, restaurants and hospitality chains want to offer handmade-style quality — minus the logistical complexity.

However, scaling up isn't as simple as multiplying the recipe. It requires a deliberate approach to ingredient ratios, fermentation timing, hydration levels, and most importantly — process control.

Why Scaling Up Artisanal Recipes is a Challenge?

Scaling artisanal recipes involves more than increasing ingredient quantities. Artisanal baking often relies on:

- Long fermentation times,

- Natural starters like sourdough,

- Manual shaping and proofing,

- Minimal processing with high hydration doughs,

- Small-batch baking for optimal crust and crumb.

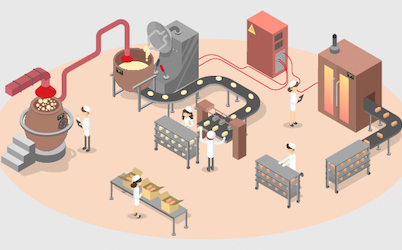

Central kitchens, on the other hand, are designed for:

- Efficiency and high-volume output,

- Consistency across batches,

- Streamlined ingredient use,

- Integration with automated processes.

The challenge lies in preserving the soul of an artisanal recipe—its texture, aroma, flavour profile—while adapting it to the realities of modern production.

1. Start with Standardization, Not Compromise

One of the biggest pitfalls is trying to “dumb down” an artisanal recipe for mass production. Instead, begin by clearly documenting your base recipe in terms of baker’s percentage. Use weights instead of volume and define variables like:

- Dough temperature

- Fermentation time (bulk and final)

- Hydration and absorption rates

- Stretch-and-fold schedules

- Final dough handling

2. Optimize Mixing & Dough Development

In small-batch baking, hand kneading or gentle mixers are sufficient. But central kitchens often use spiral or planetary mixers with higher torque and capacity. This changes gluten development and fermentation behavior.

To adapt:

- Test dough development stages in your production mixers

- Reduce mixing times if needed to avoid overoxidation

- Consider autolyse or delayed salt addition for improved extensibility

- Use temperature-controlled water to manage final dough temperature (FDT)

3. Manage Fermentation with Precision

Authentic flavor in artisan bread largely stems from proper fermentation. At scale, temperature control and timing are critical.

Key strategies:

- Use fermentation retarders or cold-proofing to extend flavor development

- Implement programmable proofers for temperature/humidity control

- Batch-ferment in dough boxes instead of bowls to simulate hand-folding

- Consider the use of dehydrated sourdough powders for consistent acidity and flavor (more on this in a future article)

4. Incorporate Functional Ingredients (Without Losing Soul)

Artisan-style baking doesn’t mean rejecting innovation. In fact, functional ingredients can be the bridge between traditional recipes and commercial-scale performance. Use high-quality bakery mixes and concentrates developed specifically to retain artisanal traits like open crumb and long crust crispiness. Smart use of functional ingredients can help in scale-up by:

- Improving dough tolerance

- Enhancing moisture retention

- Extending shelf life without preservatives

- Supporting crust and crumb development under variable conditions

5. Pre-shaping and Freezing: Central Kitchen Secrets

To balance scale with authenticity:

- Use cold bulk fermentation to slow down processes

- Pre-shape and freeze dough balls or loaves (not baked items)

- Use blast freezing to maintain structure and fermentation activity

- Store in controlled cold storage with FIFO inventory rotation

6. Train for Technique, Not Just Process

Even in central kitchens, human handling still plays a vital role. Dough characteristics like hydration, stickiness, and shaping finesse are hard to automate completely.

Upskill your kitchen staff to:

- Recognize dough readiness based on feel, not just timers

- Apply traditional folding and shaping methods efficiently

- Identify visual cues during proofing and fermentation stages

7. Batch Testing & Continuous Refinement

Scaling isn’t a one-time task — it’s a continuous cycle of observation and improvement. Regularly test your central kitchen outputs against small-batch benchmarks.

Consider:

- Weekly quality reviews with outlet chefs

- Blind taste tests between small batch and scaled product

- Adjustments in hydration or fermentation based on seasonal flour behavior

Conclusion

Scaling artisanal baking for central kitchens is no longer a compromise — it's a craft of its own. By respecting the science behind dough behaviour, leveraging the right functional tools, and building process discipline without stripping away the artistry, bakeries and HoReCa brands can deliver authentic, rustic flavour at scale.

In a world where convenience often trumps quality, staying true to artisan roots — even at volume — is not just a skill, but a competitive advantage. With the right approach, scaling up doesn’t have to mean selling out. By leveraging bakery science, controlled process adaptations and functional ingredients, central kitchens can consistently produce products that are artisanal in spirit and commercial in execution.

SwissBake®, with its portfolio of advanced bakery premixes, sourdough powders, and dough enhancers, is uniquely positioned to support this journey. For bakery brands looking to scale without losing soul, the fusion of tradition and technology is not only possible—it’s essential.