The Role of Functional Ingredients in Bakery Mixes

Modern baking is as much a science as it is an art. For industrial / commercial bakeries, HoReCa kitchens, and QSR chains, achieving consistent quality, texture and shelf life across high-output baking operations is a daily challenge. The solution? Professional-grade bakery mixes formulated with functional ingredients!

Functional ingredients are specially designed components added to bakery mixes to improve dough properties, enhance sensory attributes, extend product shelf life, and simplify production. In this article, we’ll explore the different types of functional ingredients, how they work, and why they’re indispensable for scalable, high-performance baking.What Are Functional Ingredients in Baking?

Functional ingredients are components added to bakery formulations not just for flavor or appearance, but for their technical role in shaping the behavior, texture, and quality of the final product. They:- Modify dough rheology (structure, extensibility, and elasticity)

- Enhance moisture retention and shelf life

- Support fermentation and leavening

- Improve crumb softness and crust development

- Enable uniformity in industrial settings

These ingredients are critical in premixes, concentrates, and dough systems designed for professional and industrial applications. These include:

- Enzymes

- Emulsifiers

- Fibers and hydrocolloids

- Sourdough powders

- Improvers and conditioners

- Natural preservatives

- Pre-gelatinized starches

Applications: Where Functional Ingredients Make the Difference

| Applications | Key Role of Functional Ingredients |

| Breads, Buns and Rolls |

|

| Cakes & Pastries |

|

| Pizza and Flatbreads |

|

| Gluten-Free Baking |

|

| Frozen Doughs |

|

Key Categories of Functional Ingredients and Their Roles

1. Dough Improvers and Conditioners

These blends typically contain enzymes, oxidizing agents, and emulsifiers that work synergistically to:• Strengthen the gluten network

• Improve gas retention

• Enhance dough elasticity and machinability

• Reduce proofing time

Application: Used in bread mixes, pizza dough, and laminated pastries to ensure structure and volume.

2. Advanced Enzymes

Enzymes are biological catalysts that modify the structure of starch and proteins during mixing and fermentation. Common baking enzymes include:• Amylases: Break down starch into sugars, aiding browning and fermentation.

• Proteases: Relax gluten for improved extensibility.

• Lipases and xylanases: Improve crumb softness and dough texture.

Application: Widely used in both bread and cake premixes to maintain softness and improve shelf life naturally.

3. Emulsifiers

Emulsifiers like DATEM, SSL, or lecithin help blend fat and water, stabilize air bubbles, and extend freshness. Benefits include:• Better crumb structure

• Moist mouthfeel

• Prevention of staling

• Improved batter aeration for cakes

Application: Emulsifiers are crucial in soft sandwich breads, burger buns, and sponge cakes.

4. Hydrocolloids and Fibers

These include guar gum, xanthan gum, carboxymethyl cellulose (CMC), and dietary fibers that bind water and increase dough viscosity. Benefits:• Improved moisture retention

• Better freeze-thaw stability

• Enhanced chewiness in gluten-free baking

Application: Used in high-fiber bread mixes and gluten-free baking premixes

5. Dehydrated Sourdough Powders

These functional ingredients add fermented notes without live cultures and support:• Tangy flavour and aroma

• Natural mold inhibition

• Open crumb structure

• Longer product freshness

Application: Ideal for artisan-style breads, loaves, pizza doughs, bagels, buns & more!

6. Pre-gelatinized Starches

Pre-gelatinized starches absorb water efficiently and help maintain structure in batters and doughs. Benefits:• Improve batter viscosity

• Enhance volume and softness

• Reduce crumbling in cakes

Application: Used in muffins mixes, brownies premixes and soft cakes where structural integrity is key.

7. Natural Preservatives

These include vinegar powders, cultured wheat flour, or fermented sugar blends that reduce spoilage without synthetic additives.Application: Clean-label bakery mixes that need a longer shelf life for retail and export.

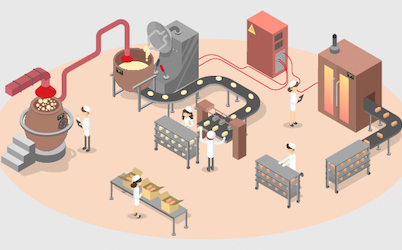

Functional Benefits for Professional Bakers

Functional ingredients in bakery mixes are not just performance enhancers—they are critical enablers of commercial baking success. For central kitchens, QSR chains, hotel commissaries, and industrial bakeries, these benefits translate into measurable gains in productivity, quality, and customer satisfaction.1. Improved Process Consistency

In high-volume environments, even small inconsistencies can lead to wastage or customer complaints. Functional ingredients ensure:• Uniform dough hydration and elasticity regardless of batch size

• Reduced variability caused by flour quality shifts or humidity

• Standardized proofing and oven spring, enabling identical output across locations

2. Enhanced Dough Tolerance

Many bakery operations rely on machines for dividing, rounding, sheeting, and shaping. Functional ingredients improve dough tolerance by:• Reinforcing gluten structure to withstand mechanical stress

• Preventing tearing or over-stretching during processing

• Allowing longer bench rest without collapse in artisan-style doughs

3. Better Yield and Waste Reduction

Improved water absorption and extensibility mean more efficient dough handling and reduced waste from sticking, tearing, or over-proofing. This leads to:• Higher finished product yield per batch

• Less downtime due to rework

• Greater control over portion sizes in automated lines

4. Shelf Life and Freshness

Freshness is a key selling point in both retail and foodservice. Functional mixes incorporate natural softening enzymes and acidity regulators that:• Extend the softness of bread or cakes for several days

• Slow staling and microbial spoilage

• Reduce dependency on artificial preservatives

5. Labor Efficiency

Functional ingredients reduce reliance on highly skilled labor:• Mixes are more forgiving and adaptable

• Recipes can be executed with shorter training cycles

• Reduced need for on-the-spot decision-making during production

This is particularly important in fast-growing chains where staff turnover is high.

6. Flexibility Across Product Ranges

Many bakery mixes are designed to be modular, allowing flavor, texture, and format variations with the same base. Functional ingredients make this flexibility possible without sacrificing core quality metrics.7. Simplified Scaling and Expansion

For bakeries expanding to new cities or countries, replicating original recipes becomes easier when using standardized mixes with embedded functional ingredients. This ensures:• Flavor consistency across outlets and every service

• Operational uniformity in franchise or satellite kitchens

• Simplified sourcing and quality control

Conclusion: Precision Baking at Scale

In a world where professional bakers must deliver artisan quality with industrial efficiency, functional ingredients are indispensable. They enable:• Better control over baking variables

• Streamlined production

• Longer product shelf life

• Enhanced eating experience

Whether you're expanding your product line or optimizing your workflow, leveraging the power of functional ingredients in bakery mixes is key to staying competitive and relevant in the modern baking industry.

SwissBake® offers a wide range of professional-grade functional premixes and bakery ingredient solutions—engineered to meet the precise needs of modern foodservice professionals.